2025.05.01

2025.05.01

Industry Information

Industry Information

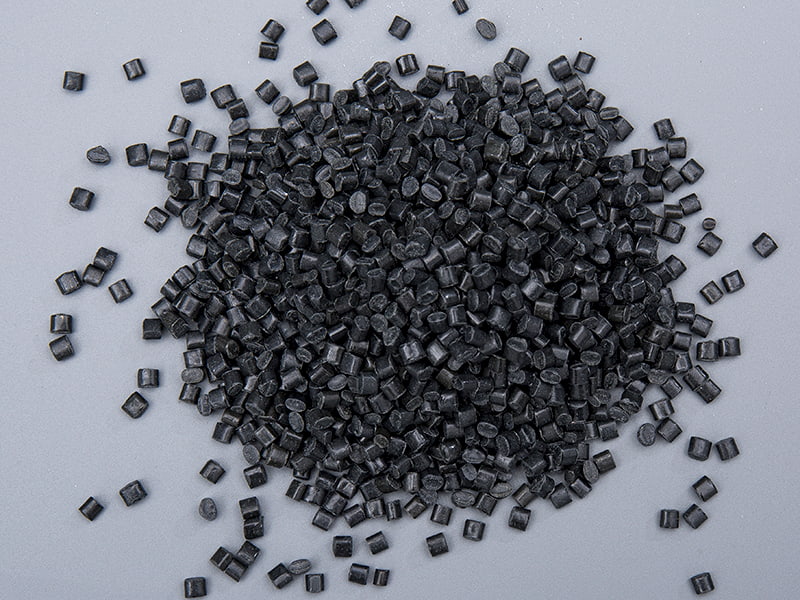

Recycled PET Raw Materials, usually derived from recycled plastic bottles, containers and other PET plastic products, are cleaned, processed and reprocessed and converted into reusable raw materials. Compared with traditional production of new plastics, the use of recycled PET raw materials can not only reduce dependence on oil resources, but also greatly reduce energy consumption and carbon emissions, thereby reducing negative impacts on the environment.

First, the energy consumption of recycling PET raw materials is much lower than that of producing new plastics. According to relevant research, the production of 1 ton of recycled PET raw materials consumes only about 50% of the energy required for raw material production. This means that packaging companies use recycled PET materials to produce products, which can significantly reduce the energy resources consumed during the production process.

In addition, the use of recycled PET materials can also help reduce the accumulation of plastic waste. In recent years, plastic pollution has gradually become the focus of global attention, especially the severity of marine plastic waste. Therefore, recycling and utilization of plastic materials, especially PET materials, has become an effective solution to reduce pollution. The widespread use of Recycled PET Raw Materials not only helps clean up plastic waste in the environment, but also opens up new possibilities for recycling plastics.

In the packaging industry, the application of Recycled PET Raw Materials is gradually increasing, especially in the packaging of consumer products such as food, beverages, daily chemicals, etc. As a high-quality and environmentally friendly alternative, recycled PET materials not only have good physical properties, but also meet the packaging industry's needs for transparency, strength and durability.

For example, many beverage and food brands have begun to use recycled PET bottles and containers to replace traditional petroleum-based plastic bottles. This transformation not only reduces production costs, but also improves the brand's environmental image and meets consumers' growing environmental protection requirements. According to relevant data, more and more consumers are becoming more inclined to choose products that use environmentally friendly packaging, which undoubtedly prompts companies to increase their investment and use of Recycled PET Raw Materials.

Additionally, Recycled PET Raw Materials is not limited to packaging of bottled products. Recycled PET materials have also been widely used in many daily consumer goods packaging. Whether it is cosmetics, detergents, or other non-food products, recycling PET raw materials can meet the packaging industry's needs for beauty, sturdiness, environmental protection, etc. In order to improve the sustainability of products, many brands have adopted recycling PET materials as their preferred material, further promoting the industry's green transformation.

As environmental regulations become increasingly strict, many countries and regions have put higher requirements on the use of plastics, forcing companies to seek alternative materials or optimize production processes. This trend undoubtedly promotes the technological innovation and application expansion of Recycled PET Raw Materials. Companies in the packaging industry are actively investing in R&D to improve the quality and performance of recycled PET materials, making them more in line with the requirements of packaging different products.

For example, the new recycled PET raw materials have been improved and have higher transparency and impact resistance, and can be widely used in the production of high-end packaging products. In addition, the supply chain for recycling PET is also constantly being optimized. From the recycling process, processing technology to supplier cooperation, packaging companies are ensuring that the supply chain of environmentally friendly packaging is more stable and efficient by improving the efficiency and quality of recycling PET materials.

From a policy perspective, more and more governments and non-governmental organizations are promoting the recycling and reuse of plastic packaging, and introducing a series of incentives to encourage enterprises to turn to environmentally friendly packaging materials. For the packaging industry, this is not only an environmental responsibility, but also an innovation opportunity. The further application and development of recycling PET materials undoubtedly provides huge market potential for the packaging industry.

Although Recycled PET Raw Materials has been widely used in the packaging industry, there are still some challenges. For example, the supply of recycling PET raw materials is still limited, especially in some areas, and the construction and improvement of recycling systems still require increased investment. In addition, quality control of recycling PET also needs further improvements to ensure its effectiveness in packaging.

However, with the continuous advancement of technology and the increase in market demand, the application prospects of recycling PET raw materials are still broad. Industry experts predict that with the increase in environmental protection requirements of the global packaging industry, the use of recycled PET materials will further grow and gradually become the mainstream trend in the packaging industry. More and more companies will improve the quality and supply capacity of recycled PET raw materials through investment recycling and reuse technologies to meet the market's demand for environmentally friendly packaging materials.