2025.05.22

2025.05.22

Industry Information

Industry Information

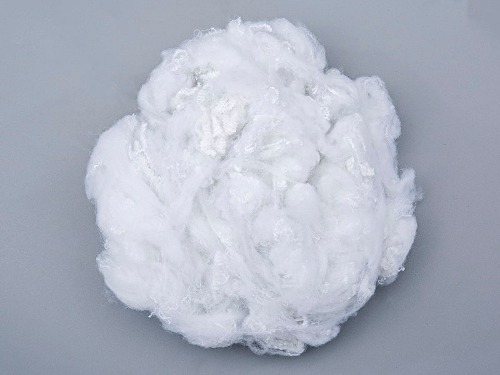

As the automobile industry continues to develop towards lightweight, environmental protection and intelligence, nonwovens for the automotive, as one of the key materials, has ushered in broad prospects and significant technological breakthroughs in its application in the automotive interior field. With its excellent performance, environmental protection characteristics and cost advantages, non-woven fabrics have become the core material for improving the quality and functions of automobile interiors.

Car interiors have extremely strict requirements on materials, which not only ensure comfort and aesthetics, but also meet durability, safety and environmental protection. As an important part of nonwovens for the automotive, nonwoven fabrics are widely used in interior parts such as car ceilings, door panels, seat linings and carpets due to their lightweight, high-strength and good sound insulation properties.

In recent years, the strengthening of environmental protection regulations has prompted non-woven fabric manufacturers to accelerate green transformation, use renewable materials and environmentally friendly processes to manufacture non-woven fabrics to reduce carbon emissions and release of harmful substances. This not only conforms to the green manufacturing trend of the automotive industry, but also meets consumers' demand for environmentally friendly products and promotes the upgrading of automotive interior materials in a sustainable direction.

Technological innovation is the core driving force for nonwovens for the automotive application expansion. The new composite non-woven fabrics give the car interior more functionality by combining them with functional materials, such as fire resistance, flame retardant, waterproof and breathable, antibacterial and antifouling, etc., improving the safety and service life of the interior.

In addition, advanced spunbond and needle-punching processes continuously optimize the structure and performance of non-woven fabrics, enhance their softness and elasticity, and enhance their driving comfort. The application of intelligent manufacturing technology has achieved precise control and stable quality of the non-woven fabric production process, providing more reliable guarantees for automotive interior materials.

In the future, nonwovens for the automotive will continue to make efforts in the direction of intelligence and greening. The integration of intelligent materials and sensing technology will enable non-woven fabrics to have more interactive functions, such as environmental perception and health monitoring, and promote the intelligent upgrade of automotive interiors.

At the same time, the deepening application of environmental protection technology will promote the use of non-woven fabrics with a higher proportion of bio-based and recyclable materials, helping the automotive industry achieve the goal of circular economy. With the dual driving force of technology and market demand, non-woven fabrics will be more widely used in the field of automotive interiors.

The application prospects for nonwovens for the automotive in automotive interiors are very broad, and technological innovation continues to promote its performance improvement and function expansion. The industry needs to continue to increase R&D investment, promote green manufacturing and intelligent applications, and help automotive interior materials move into a new era of high-quality and sustainable development.